Materials form the basis of our physical environment. Since the dawn of humankind, new uses of materials have steadily driven societal development. Materials innovation is important in fostering technological growth that promotes the wellbeing of society. Novel materials are needed to meet the challenges of energy transition, sustainability, circular economy and critical raw materials, which are dominant themes in the program. This programme covers a broad range of material classes from “ordinary” construction materials to novel materials for high tech applications, all relevant to increase the competitiveness of Dutch industry and improving our society.

Programme duration: 4 years | 2024 - 2027

Problem statement

Materials innovations are the driver for the green transition. The first point of importance, especially in face of the strong urge for supply chain resilience, is the circular economy where materials flow back into the production chain at the end of the life as secondary raw materials. Circularity will be a cross-cutting theme in future materials research in all material classes. The second key driver are sustainability and the energy transition. To achieve the net-zero greenhouse gas emission goals material innovations are required, ranging from functional materials for solar panels, to battery materials and strong composite materials for wind turbines. In the context of sustainability, the emerging hydrogen economy is demanding hydrogen resistant materials. With the ever-growing computational power, high performance computing, big data and AI play an increasingly important role in the digitalisation for simulating material and product performance, screening of new materials, and optimising production processes.

Objective

The goal of this programme is to develop a sustainable high-tech industry in the Netherlands focussing on the materials domain. Materials research and innovation will lead to higher efficiencies of product and processes, higher quality and novel applications, increasing the competitiveness of Dutch industry and improving society, keeping in mind the planetary limits regarding the use of resources.

Approach

Multiple projects in the field of materials science will be initiated from this programme aiming to translate the knowledge generated from science into new or improved products and services – a crucial step towards providing large impact on industry and society. The scientific outputs of the projects solve a problem currently hindering economic growth or bring added value to existing business or society. The result will be an improved product or process, or higher materials or energy savings that are needed for the transition towards a more sustainable, resilient and circular economy.

Relation with urgent transitions, KIAs and technologies

Materials innovations are essential for the urgent energy transition, circular economy and resource autonomy. Advanced materials are recognized as key technology for economic growth and societal improvement.

Programme consortium

M2i | NLR | TU Delft | University of Twente | TU Eindhoven | University of Groningen | Wageningen University & Research

Urgent transitions

Key enabling technologies

Energy transition

Circular economy

Digitalisation & Smart Industry

Knowledge and Innovation Agendas (KIAs)

KIA Key Enabling Technologies

KIA Klimaat en Energie

KIA Circulaire Economie

KIA Maatschappelijk

Verdienvermogen

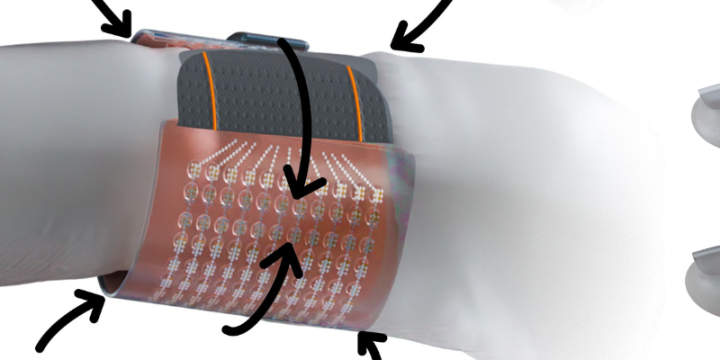

Wearable haptics for the virtual world

Assessment on hydrogen-based green steelmaking for future Dutch Steel industry

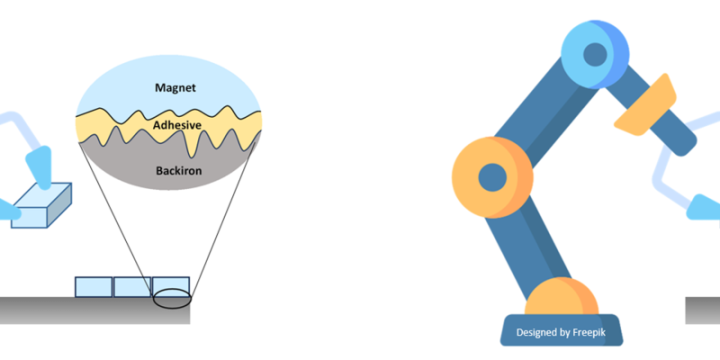

Adhesive bonding of magnet-to-metal interfaces

Recycled rubber materials as novel ingredient for product design

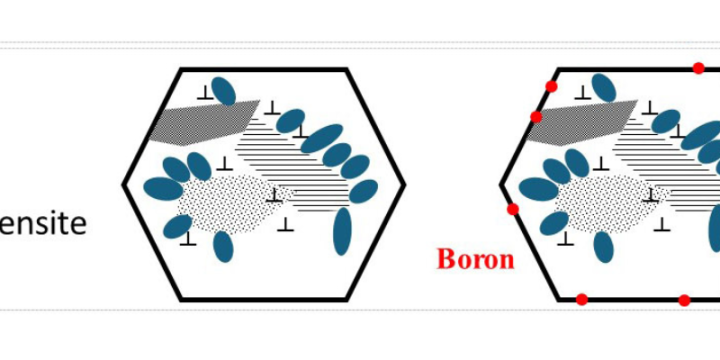

Understanding the effect of boron on the formation of bainite and martensite and resulting mechanical properties

Dynamic Wetting in Hot Dip Galvanizing

Improved temper roll-force prediction through microstructural modelling

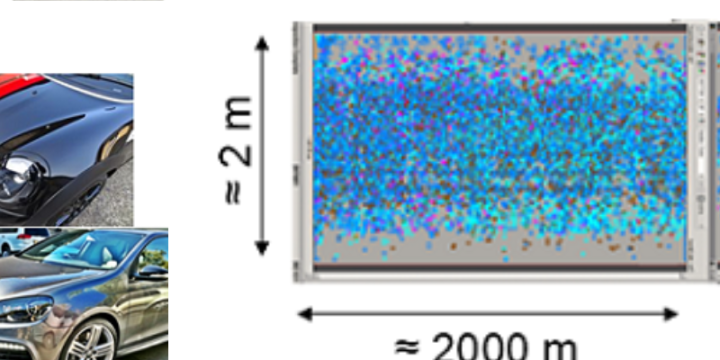

Quantitative and Spatially Resolved Mechanical and Electrical Characterization of high tech functionalized Pigments

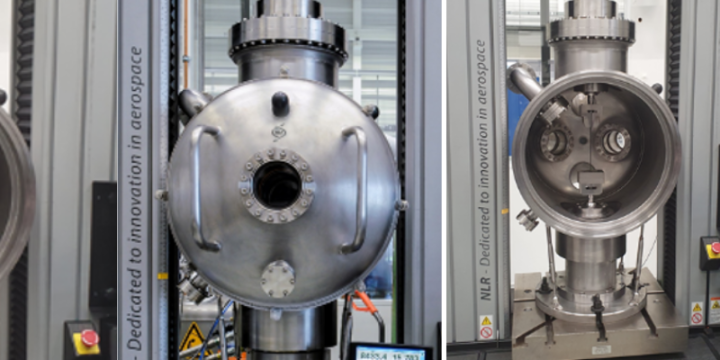

Feasibility MATPROP @20K

Programmes and projects

Holland High Tech supports programmes and projects in the sector High Tech Systems and Materials. Carried out in close collaboration between public and private partners within the mission-driven and innovation policy. Here is an overview funded R&D programmes and projects by Holland High Tech.